Fischer Technology’s Rahul Nair explains the benefits of using nanoindentation to measure a coating’s mechanical properties. #basics #measurement-testing

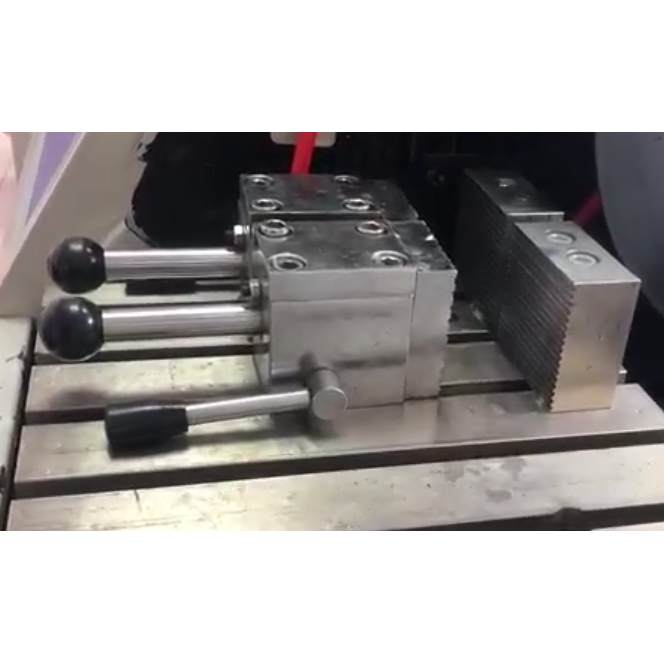

Q. Our customer has asked us to test the mechanical properties of the coatings we apply. How can we do this, and why is this important? Rockwell Hardness Testing Machine

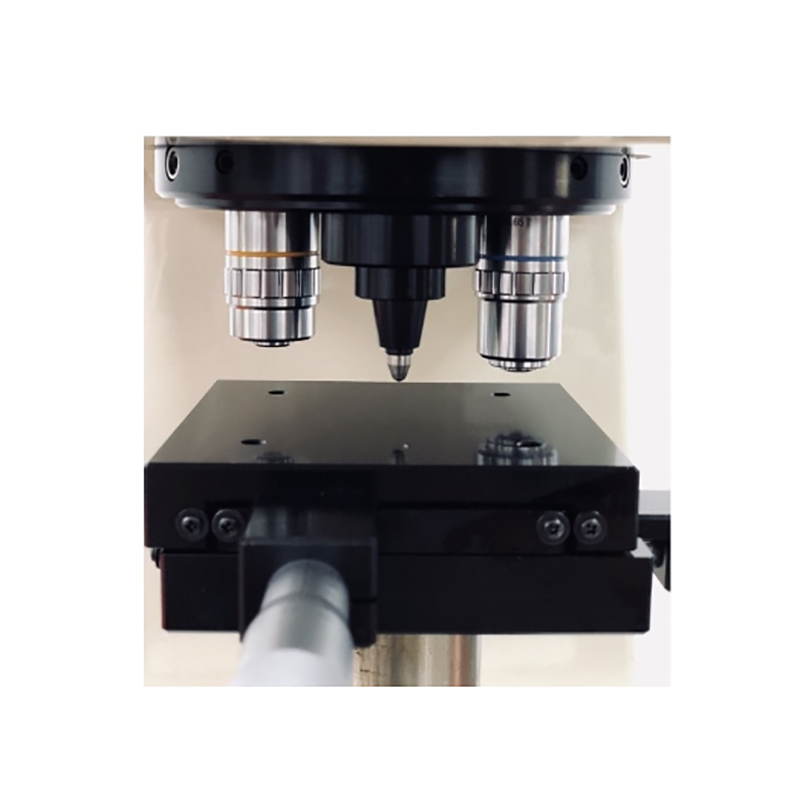

A. Nanoindentation measures a coating’s mechanical properties with very specific and controlled depth penetration into the coating. A loose rule of thumb is to control the depth of indentation to approximately one-tenth the thickness of the coating to eliminate effects from the material beneath it. Traditional testing using Rockwell and Vickers indentation testers cannot control the indentation to these shallow depths.

Here are the top five features to look for in nanoindentation instrumentation:

Rahul Nair is a product specialist at Fischer Technology Inc. Visit fischer-technology.com.

Powder coating is one of the most durable finishes that can be applied to industrial manufactured products, and offers excellent corrosion protection and is very safe because of its lack of volatile organic compounds. To understand the powder coating process you should start with the fundamentals.

Learn more on this inexpensive and highly efficient process.

My company fabricates aluminum and steel pedestrian bridge railing among other bridge parts. We recently got an aluminum railing job that called for “Type I” anodizing per MIL-A-8625. There was no anodic coating thickness called out. We are not anodizers and we are at a loss as to how to write up a meaningful anodizing specification for this railing.

Hardness Vickers Copyright © 2023 Privacy Policy [Log On]